Abantu babona utshintsho olukhulu kwindlela aigranulator yeplastikiisebenza namhlanje. Uhlaziyo lwakutsha nje, njengezoluvo ezikrelekrele kunye neenjini zokonga amandla, uncedoigranulator yeplastiki yezoshishinoabasebenzisi banciphisa iindleko kwaye banyuse imveliso. Abaninzi abavelisi beplastiki yegranulator ngoku bongeza iindawo ezinqabileyo zokunxiba, ukwenza nganyeigranulator enamandlahlala ixesha elide kuInkqubo yokurisayikilisha.

| Ukusungula izinto ezintsha | Ubuchule bokusebenza | Iindleko-Ukusebenza |

|---|---|---|

| I-Smart Technologies | Ukubeka iliso ngexesha langempela | Iyanciphisa ixesha lokuphumla |

| Ukusebenza kakuhle kwamandla | Amandla amancinci afunekayo | Yehlisa iindleko zokusebenza |

| Izinto eziphucukileyo | Ukuqhekeka okumbalwa | Igcina kwizinto ezitshintshiweyo |

Izinto eziphambili zokuThatha

- Iinzwa ze-Smart kunye ne-automationukuphucula ukusebenza kwegranulator yeplastiki ngokunciphisa ixesha lokuphumla kunye nokunyusa umgangatho wemveliso.

- Iinjini zokonga amandlakunye noyilo oluphucukileyo olusezantsi lokusetyenziswa kwamandla kunye nokunciphisa iindleko zokusebenza ngelixa uxhasa iinjongo zokusingqongileyo.

- Iimodyuli, iigranulator ezinokwenziwa ngokwezifiso zilingana neemfuno ezahlukeneyo, zenza ukuba ukurisayikilisha kukhuseleke, kube lula, kwaye kusebenze ngakumbi kumashishini amaninzi.

Ukuzenzekela kunye neShishini 4.0 kwiTekhnoloji yePlastiki yeGranulator

I-Smart Sensors kunye ne-IoT Integration

Izinzwa ezihlakaniphile zitshintshile indlela abaqhubi abalawula ngayo igranulator yeplastiki. Ezi zinzwa zilandelela iinkcukacha ezibalulekileyo, njengobushushu kunye nesantya sokutya, ukugcina oomatshini besebenza kakuhle. Abaqhubi basebenzisa izixhobo zokulawula ubushushu ukuthintela izinto ekunyibilikeni. I-automatic knife reversal sensors inceda ukuphepha iijam, ngoko ke inkqubo ayiyeki. Izinzwa zokondla ngobuchule zilungelelanisa indlela izinto ezikhawuleza ngayo ukungena kumatshini, zigcina yonke into izinzile.

- Abenzi boluvo bolawulo lobushushu bajonga ubushushu bokuqhuba.

- Izinzwa ezizenzekelayo zokuguqula imela zibhaqa iijam kwaye zigcine inkqubo ihamba.

- Abenzi boluvo bokutya okukrelekrele badibanisa isantya segalelo kunye nomthamo womatshini.

Ukudityaniswa kwe-IoT kuzisa izibonelelo ezingakumbi. Abaqhubi banokujonga impilo yomatshini naphi na besebenzisa iliso elikude. Uxilongo lwexesha lokwenyani kunye neengxaki ze-PLC zokudibanisa kwangethuba. Ugcino oluqikelelwayo lunceda ukucwangcisa ukulungiswa ngaphambi kokuba ukonakala kwenzeke. Oku kunciphisa ixesha lokuphumla kwaye konga imali. Izinzwa zikwajonge imiba efana nokuvala ukufa okanye ukugcwala kwemoto. Iiplatifti ezisekelwe kwifu zithumela izikhumbuzo zokugcinwa, ngoko ke abaqhubi abayilibali imisebenzi ebalulekileyo.

Ingcebiso: Izinzwa ezihlakaniphile kunye nolawulo lwe-IoT lunceda abaqhubi ukuba babambe iingxaki kwangoko, bagcine oomatshini besebenza ixesha elide, kwaye baphucule umgangatho wemveliso.

UPhuculo lweNkqubo eqhutywa yi-AI

Iinkqubo eziqhutywa yi-AI zenza imisebenzi yeplastiki yegranulator ibe nobuchule. Ezi nkqubo zisebenzisa idatha ukulungisa useto olufana nobushushu kunye nesantya se-screw. Abaqhubi babona izinto ezilahliweyo ezimbalwa kunye neepellets ezingaguqukiyo. I-AI inceda ukucwangcisa ulondolozo ngokubona ukunxiba kwezixhobo ngaphambi kokuba kubangele ingxaki. Oku kugcina oomatshini besebenza kwaye kunciphisa ukulungiswa okumangalisayo.

- I-AI ifumana iisetingi ezingcono kakhulu kwibhetshi nganye, ukuthoba amaxabiso okulahlwa.

- Ukugcinwa kwangaphambili kwandisa ixesha kunye nokuthembeka kwe-asethi.

- Ulawulo lwekhwalithi oluqhutywa yidatha luphucula ukufana kwepellet kwaye lunyuse amaxabiso emveliso yodidi lokuqala.

- Uyilo olugcina umbane kunye nokubuyiswa kobushushu kunokunciphisa ukusetyenziswa kwamandla ukuya kuthi ga kwi-30%.

I-AI ikwanceda abaqhubi baphephe iimpazamo. I-automation kunye ne-AI zisebenza kunye ukugcina ubungakanani bepellet kunye nomgangatho uzinzile. Xa i-AI, i-automation, kunye ne-IoT ijoyina imikhosi, i- throughput iyenyuka kwaye inkunkuma iyehla. Ezinye izibonelelo zisebenzisa umatshini wokufunda ukubona iingxaki kunye neemfuno zogcino lwengqikelelo. Olu lawulo luhlakaniphileyo alukho umgangatho okwangoku, kodwa iinkampani ezininzi ziceba ukuzisebenzisa kungekudala. Ikamva liza kuzisa inkqubo yokuzimela ngakumbi kunye neempawu eziqikelelwayo.

Iirobhothi kunye nokutya okuzenzekelayo

Iirobhothi kunye neenkqubo zokutyisa ezizenzekelayo zenze izibonelelo zeplastiki zegranulator zikhuselekile kwaye zisebenza kakuhle. I-Vibratory feeders zisebenzisa izinzwa kunye nempendulo ukuhambisa izinto ngokuchanekileyo. Abaqhubi akufuneki baphathe iingxowa ezinzima okanye bavule iingxowa ezivulekileyo kwakhona. Iirobhothi kunye nezixhobo zokuhambisa imitha zibe yigranulator, ukuthintela ukutyisa kakhulu okanye ukungondleki. Oku kugcina oomatshini bekhuselekile kwaye kunciphisa ixesha lokuphumla.

Iinkqubo zokutyisa ezizenzekelayo zinciphisa iimfuno zabasebenzi. Abasebenzi bachitha ixesha elincinci kwimisebenzi yezandla kwaye bajongana neengozi ezimbalwa ukusuka eluthulini okanye izixhobo ezibukhali. Izixhobo zePlastiki ezizenzekelayo zigcina imathiriyeli ihamba, ukuze oomatshini bangapheli. Ukuzenzekela kwakhona kunciphisa iingozi ezinxulumene nokuphathwa ngesandla. Amaziko abona iziphumo ezingcono zokhuseleko kunye nesidingo esincinci songenelelo lwabasebenzisi.

Qaphela: Iirobhothi kunye neenkqubo zokutyisa ezizenzekelayo zikhusela abasebenzi kwaye zinceda oomatshini basebenze kakuhle, zenza imisebenzi yeplastiki yegranulator ikhuseleke kwaye ithembeke ngakumbi.

UkuSebenza kwamandla kunye noZinzo kwiiGranulator zePlastiki

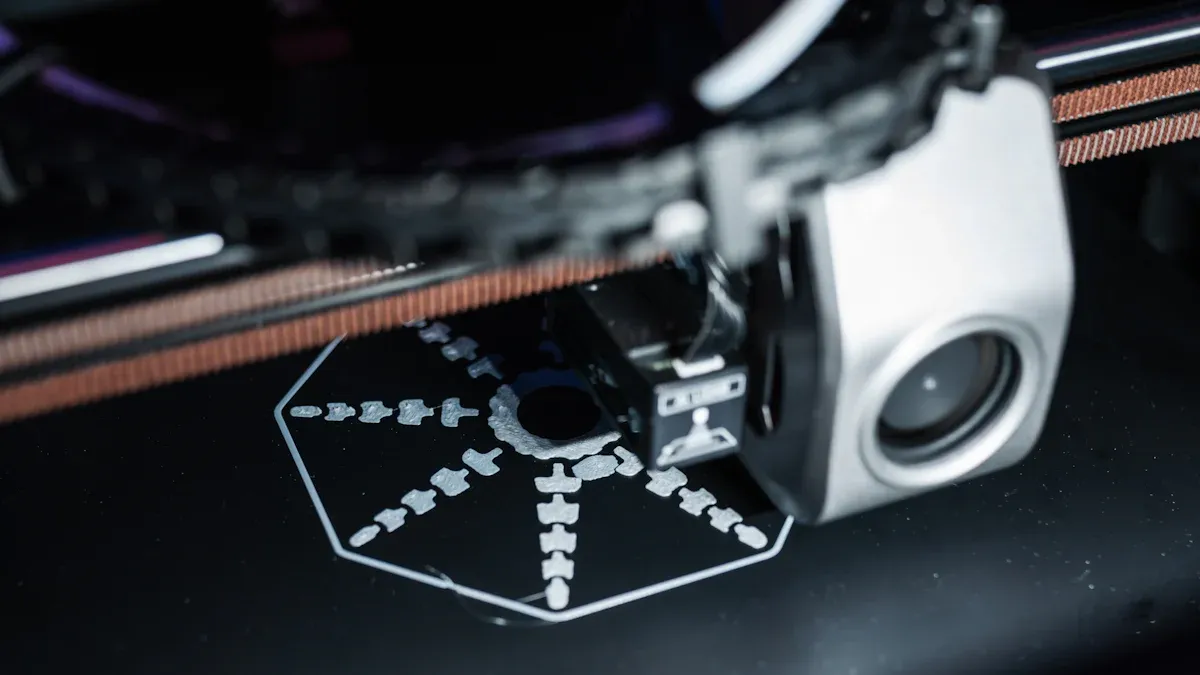

.jpg)

IiNkqubo zeeMoto eziFanelekileyo

Iinkqubo zeemoto ezikumgangatho ophezulu zitshintshile indlela amaziko asebenzisa ngayo amandla ekuhlaziyweni kweplastiki. Ezi motors zisebenzisa amandla amancinci kunezo zemveli. Abaqhubi babona amatyala aphantsi ombane kunye neengxaki ezimbalwa zokulondoloza. Izityumli zeplastiki zanamhlanje ezineenjini eziphezulu kunye ne-variable frequency drives (VFDs) zinokunciphisa ukusetyenziswa kwamandla ngama-25-30%. Amaziko amaninzi atshintshela kwezi motor asebenzisa isixa esifanayo seplastiki kodwa achithe kancinci kumandla.

- Iimotor eziphezulu zilungelelanisa amandla azo ngokusekelwe kumthwalo. Oku kuthetha ukuba abachithi amandla xa umatshini ungagcwalanga.

- Iigranulator ezinesantya esisezantsi ezineenjini zibaleka kancinci. Benza ubushushu obuncinci kwaye baguge ngokukhawuleza, okusindisa zombini amandla kunye neendleko zokulungisa.

- Iisistim zolawulo ezikwinqanaba eliphezulu zinceda imotor ukubaleka ngesantya esilungileyo somsebenzi ngamnye. Oku kugcina ukusetyenziswa kwamandla kuphantsi kunye nokusebenza okuphezulu.

- Abanye oomatshini bade babe neenkqubo zokubuyisela umbane. Ezi nkqubo zibamba ubushushu obongezelelweyo kwaye zibuguqule ube ngumbane, zonga imali engakumbi.

Abaqhubi bafumanisa ukuba iindleko eziphezulu zangaphambili zezi motor zihlawula ngokuhamba kwexesha. Bachitha imali encinci kumandla kunye nokulungiswa, okwenza yonke inkqubo ibe yinto ezinzileyo.

Uyilo Lokonga Amandla

Abavelisi ngoku bakha iigranulator zeplastiki ezineempawu ezintle ezonga amandla yonke imihla. Olu tshintsho loyilo lunceda iinkampani ukuba zihlangabezane neenjongo zazo eziluhlaza kunye neendleko eziphantsi. Itheyibhile engezantsi ibonisa ezinye zezona mpawu zisebenzayo zokonga umbane kunye noncedo lwazo:

| Uyilo loyilo | INzuzo yokonga amandla |

|---|---|

| Ukonga amandla eenjini zamahashe aphantsi | Ukunciphisa ukusetyenziswa kwamandla ngokubanzi |

| Izindlu zokusika ezingenasikrini | Yehlisa isantya se-rotor kwaye inciphisa izohlwayo, iphucula ukusebenza kakuhle kwamandla |

| Isantya serotor esisezantsi kakhulu | Yehlisa ukusetyenziswa kwamandla ngelixa igcina umgangatho wegranule |

| Irotor enamazinyo amaninzi enamazinyo aphinde alolwe | Igcina ukusebenza kakuhle kokusika, ukunciphisa inkcitho yamandla ngokuhamba kwexesha |

| Uyilo lwetorque ephindwe kabini | Ukuphatha izinto ezinzima ngokufanelekileyo, ukunciphisa inkunkuma yamandla |

| Uyilo lwemela ye-Twinshear | Ukuphucula ukusebenza kakuhle kokusika, ukusebenzisa amandla amancinci |

| Ukwahlula igumbi | Ivumela ukucoca ngokukhawuleza, ukunciphisa ixesha lokuphumla kunye nokusetyenziswa kwamandla |

| Ukomelezwa komsebenzi onzima wekhusi umqamelo | Ukwandisa ukuqina, ukunciphisa ukulahleka kwamandla ngenxa yokunxiba |

Ezinye iimodeli ezintsha, ezifana ne-CMG Granulators 'EV Series, zisebenzisa iimilo zokusika eziphambili kunye neenkqubo zokuqhuba kakuhle. Olu tshintsho lunokucutha ukusetyenziswa kwamandla ukuya kutsho kuma-50% xa kuthelekiswa noomatshini abadala. Uninzi logcino lwamandla luvela ekukhetheni ubungakanani bemoto obufanelekileyo kunye nokusebenzisa ulawulo oluwonga amandla. Abasebenzi abasebenzisa olu yilo babona amathontsi amakhulu kumatyala abo amandla kunye nexesha elincinci lokulungiswa.

Icebiso: Ukukhetha igranulator yeplastiki eneempawu zokonga amandla kunceda iinkampani zonge imali kwaye zikhusele indalo engqongileyo ngaxeshanye.

I-Eco-Friendly kunye ne-Recyclable Components

Uzinzo ngoku yeyona nto iphambili kwiinkampani ezininzi. Bafuna oomatshini abahlala ixesha elide kwaye benze inkunkuma encinci. Amacandelo e-Eco-friendly kunye ne-recyclable kwiigranulator zeplastiki zinceda ukufikelela kwezi njongo. La malungu asebenzisa izixhobo ezimbalwa kwaye enze ukurisayikilishwa kube lula.

- Amalungu e-Eco-friendly anciphisa inkunkuma yeplastiki kwaye alondoloze amandla.

- Ubuchwephesha obukwinqanaba eliphezulu, njengokuhlela okuqhutywa yi-AI, kuphucula umgangatho weeplastiki ezisetyenzisiweyo.

- Imigaqo, efana neBasel Convention kunye neRoHS, ityhala iinkampani ukuba zisebenzise oomatshini abaluhlaza.

- Inkuthazo yezemali, njengekhefu lerhafu, ikhuthaza utyalo-mali kwi-eco-friendly izixhobo zokurisayikilisha.

- Iiyunithi zemodyuli kunye nezihambayo zokurisayikilisha zinciphisa ukukhutshwa kwezinto ezikhutshwayo kwaye zenza ukuba ukurisayikilishwa kufikeleleke ngakumbi.

Abavelisi ngoku bagxile ekuhlangabezaneni nemigangatho yokusiNgqongileyo, iNtlalo, kunye noLawulo (ESG). Basebenzisa uyilo olusebenza ngamandla kunye nezixhobo ezikhuselekileyo ukuhlangabezana nemithetho engqongqo. Olu tshintsho lunceda iinkampani zilandele umthetho kwaye zibonise abathengi ukuba bayayikhathalela iplanethi. Ngokusebenzisa i-eco-friendly granulators zeplastiki, iinkampani zixhasa uqoqosho lwesetyhula kunye nokunciphisa i-carbon footprint.

UkuPhathwa kweMathiriyeli ePhakamileyo kunye nokwenza ngokwezifiso kwiiGranulator zePlastiki

Iimodyuli kunye noYilo oluQinisekileyo

Abavelisi ngoku bakha iimodyuli kunye neegranulator ezihlangeneyo ezingena kwiindawo ezixineneyo. Aba matshini banceda iindawo zokusebenzela ezincinci kunye neefektri ezinkulu zonga indawo yomgangatho. AbaSebenzi banokubeka iigranulator ezixineneyo kanye ecaleni kwemigca yemveliso. Olu cwangciso lubavumela ukuba baqhube i-scrap ngokukhawuleza, ethoba iindleko zokuphatha izinto. Uyilo lwemodyuli luvumela ukuphuculwa ngokukhawuleza xa imveliso ifuna utshintsho. Amaqela anokutshintsha iincakuba okanye iirotor kwiiyure nje ezimbalwa. Oku bhetyebhetye kuthetha ixesha eliphantsi lokuphumla kunye nokugcinwa ngokukhawuleza. Iiyunithi ezininzi zikwabandakanya ukucutha ingxolo kunye neempawu zokunciphisa uthuli, okwenza indawo yokusebenza ikhuseleke kwaye izolile. Izixhobo zoluvo ezihlakaniphileyo kunye nexesha lokwenyani zinceda abaqhubi babone iingxaki kwangethuba, ngoko ke ulungiso lwenzeka phambi kokonakala.

Ingcebiso: Uyilo oluyimodyuli kunye nolubambeneyo lwenza ufakelo lube lula kwaye luxhase ukurisayikilishwa kwendawo, nto leyo ekhulisa ukusebenza kakuhle kwaye ithobe imingeni yogcino.

I-Processing Complex kunye ne-Mixed Plastics

Ukurisayikilisha iiplastiki ezixutyiweyo kunzima, kodwa ubugcisa obutsha bukwenza kube lula. Iinkqubo zokuhlela ezinikwe amandla e-AI zisebenzisa iikhamera kunye neenzwa zokwahlula iintlobo ezahlukeneyo zeeplastiki. Izixhobo zokuhlela zeMagnetic kunye ne-optical zisusa isinyithi kunye nolunye ungcoliseko phambi kwegranulation. Abanye oomatshini basebenzisa iikhemikhali zokurisayikilisha ukuqhekeza iiplastiki zibe ngamalungu azo asisiseko. Ezi ndlela zinceda abaqhubi ukuba bafumane imathiriyeli ecocekileyo esetyenzisiweyo kunye nomthamo ophezulu. I-Vibratory feeders kunye nezikrini zisasaza iplastiki, ngoko ke ukuhlelwa kusebenza ngcono. La manyathelo akhusela igranulator yeplastiki kunye nokuphucula umgangatho weepellets ezihlaziyiweyo. Abaqhubi babona amaxesha okusebenza ngokukhawuleza kunye neendleko eziphantsi zamandla.

- Ukuhlela okuqhutywa yi-AI kuphucula ubunyulu.

- Iinkqubo zeMagnetic kunye ne-optical zisusa ungcoliseko.

- Ukurisayikilishwa kweekhemikhali kudala imathiriyeli ekumgangatho ophezulu.

Izisombululo ezilungiselelwe iiMfuno zoShishino

Iinkampani zifuna iigranulator ezihambelana neemfuno zabo ezizodwa. Abavelisi baphulaphula izicelo zabathengi kunye noomatshini bokuyila abaneempawu ezikhethekileyo. Ezinye iiyunithi zineekhamera zokubeka iliso ngexesha langempela kwiindawo eziphambili. Izixhobo zokujonga isinyithi zigcina izinto ezingafunekiyo ngaphandle, zenza iimveliso zikhuseleke. Ulawulo olucwangcisiweyo luvumela abaqhubi ukuba babeke ubushushu, isantya kunye noxinzelelo. Iinkqubo zokukhupha i-vacuum zisusa uthuli kunye nokufuma, zigcina imveliso icocekile. Ukupholisa kwamanzi kunqanda amasuntswana ekudibaneni. Ezi mpawu zesiko zinceda iinkampani zonge amandla kwaye zihlangabezane nemithetho engqongqo yokusingqongileyo. Amaqela afumana uqeqesho kunye nenkxaso emva kokufakwa, ngoko ke basebenzisa oomatshini kakuhle.Izisombululo zesikonceda iinkampani zikhule kwaye zihlale zithembekile.

| Uphawu lwesiko | Inzuzo |

|---|---|

| Ukubeka iliso ngexesha langempela | Ukuphucula ulawulo lomgangatho |

| Ukufunyanwa kwesinyithi | Ukwandisa ukhuseleko |

| Ulawulo olucwangcisiweyo | Yandisa ukusebenza kakuhle |

| Vacuum exhauum | Igcina imveliso inyulu |

| Ukupholisa amanzi | Ithintela ukuqumba |

Impembelelo yeMarike kunye nokwamkelwa kwePlastiki yeGranulator Innovations

Ukukhawulezisa ukuFumana kwiShishini

Abavelisi kunye nabahlaziyi bahamba ngokukhawuleza ukuba bamkele itekhnoloji entsha yeplastiki yegranulator. Babona izibonelelo ezinkulu ezivela kwiimpawu ezifana ne-IoT-enabled monitoring kunye ne-AI-drived predictive maintenance. Olu phuculo lunceda ukunciphisa ixesha lokuphumla kunye neendleko eziphantsi. Ukuphuculwa koyilo lweblade kunye nezixhobo ezomeleleyo zivumela iinkampani ziqhube iiplastiki ezixubeneyo ngengxaki encinci. Imithetho yokusingqongileyo, efana neSicwangciso sokuSebenza seSetyhula ye-EU kunye noXanduva loMvelisi owandisiweyo, ityhala iinkampani ukuba zityale imali koomatshini abaphambili. Abantu abaninzi bakhathalele uzinzo, ngoko ke imfuno yegranulator ehlangeneyo, ehambayo, kunye neyonga amandla ihlala isonyuka. Amaqela asebenza kunye ukuphuhlisa nokusungulaiimodeli ezintshaNgesantya. Inkuthazo yezoqoqosho, njengeendleko zokusebenza eziphantsi kunye nokuthobela lula, nazo ziyakukhawulezisa ukwamkelwa. Ukukhula komelele kuMntla Merika, eYurophu, naseAsia Pacific ngenxa yemfuno yentengiso kunye noxinzelelo lolawulo.

- Iimpawu ze-IoT kunye ne-AI zonyusa ukusebenza kakuhle.

- Uyilo olutsha lweblade luphatha iiplastiki ezixubeneyo.

- Imigaqo kunye neenjongo zozinzo ziqhuba utyalo-mali.

- Oomatshini ababambeneyo nabahambayo bahlangabezana neemfuno eziguquguqukayo.

- Iinzuzo zoqoqosho zikhuthaza ukuphuculwa.

Ulawulo lweNtlanganiso kunye neMigangatho yokusiNgqongileyo

Iinkampani zijongene nemithetho engqongqo yokuphinda isetyenziswe kunye nolawulo lwenkunkuma. Ukwenziwa kwezinto ezintsha kwitekhnoloji yegranulator yeplastiki kubanceda bahlangabezane nale migangatho. I-automation kunye ne-AI yokuhlela izinto kunye nokususa ukungcola ngokuchaneka okuphezulu. Ukucoca ngokungenamanzi kunye neendlela zokucoca ngokomisa zinciphisa ukusetyenziswa kwamanzi kwaye zinciphise amanzi amdaka. Iimodyuli zokubuyisela amandla zibamba ukushisa kwaye ziguqule zibe ngumbane, zinciphisa imfuno yamandla. Iinkqubo zokubeka iliso zedijithali zilandelela ukuthotyelwa kunye nokugcinwa ngexesha langempela. Oomatshini abaninzi ngoku balandela imithetho ye-RoHS ukunciphisa izinto eziyingozi. Imigangatho ye-elektroniki eluhlaza inceda ukunciphisa ukukhutshwa kwekhabhoni. Iisistim zokuhluza ezikwinqanaba eliphezulu zigcina izinto ezikhutshwayo kunye namanzi amdaka ephantsi. Uyilo lweemodyuli lwenza kube lula ukulungelelanisa izixhobo kwimimiselo emitsha.

- I-Automation kunye ne-AI iphucula ukuhlenga nokugcinwa.

- Ukucoca okungenamanzi kusindisa izixhobo.

- Ukubuyiswa kwamandla kunciphisa ukusetyenziswa kwamandla.

- Ukuhlolwa kwedijithali kuqinisekisa ukuthotyelwa.

- Izixhobo zemodyuli ziqhelana nokutshintsha imithetho.

Ukwandiswa kwezicelo kunye namaCandelo eMarike

Ukwenziwa kwezinto ezintsha kwiigranulator ezinobunzima obuvula iingcango kwiimarike ezintsha. Iinkampani zisebenzisa aba matshini ngaphezu kokusebenza ngokutsha. Itheyibhile engezantsi ibonisa amanye amacandelo akhulayo kunye nokusetyenziswa kwawo okuphambili:

| ICandelo leMarike ekhulayo | Izicelo zokuqhuba / abaqhubi bokuKhula |

|---|---|

| Ukwenziwa ngokutsha kwePlastiki eZinzileyo | Ukusetyenzwa kwenkunkuma yasemva komthengi kwiigranuli ezinokusetyenziswa kwakhona; ixhasa uqoqosho lwesetyhula kunye nozinzo. |

| I-Granulation ye-Pharmaceutical | I-granulator ezomileyo kwizinto eziphathekayo ezinobumanzi; i-high-shear granulation yamachiza anzima; idibana nemimiselo engqongqo. |

| Ukulungiswa kokutya | Ukwenza iigranules zesithako ezifanayo; iphucula umgangatho wemveliso; ihlangabezana nesidingo esikhulayo sokutya okucoliweyo. |

| Ubuchwephesha bokuRecycling obukwinqanaba eliphezulu | Izisombululo ezisebenzayo ezivela kubadlali abaphambili; kugxininise kugranulation engcono kunye neendlela zokurisayikilisha. |

| Ukukhula kweNgingqi kwi-Asia-Pacific | Ukwandiswa eTshayina, eIndiya, naseVietnam; imfuno enamandla yeegranulator kumashishini amaninzi. |

Olu setyenziso lutsha lunceda iinkampani ukuba zikhule kwaye zifikelele kubathengi abaninzi. Igranulator yeplastiki ngoku idlala indima ephambili kumacandelo amaninzi, ukusuka ekusetyenzisweni ngokutsha ukuya ekutyeni nakumayeza.

Imiceli mngeni kunye nekamva leeGranulator zePlastiki

Izithintelo Zokukhuliswa Komntwana Wabanye Abantu Ngokubanzi

Iinkampani ezininzi zifuna ukuphucula iinkqubo zazo zokurisayikilisha, kodwa imiqobo emininzi iyayithothisa. Iindleko eziphezulu zangaphambili zenza ukuba kube nzima ukufikelela koomatshini abaphambili, ngakumbi kumashishini amancinci naphakathi. Ngokomzekelo, i-shaft-shaft shredders ingaxabisa i-$ 10,000 ukuya kwi-$ 50,000, ngelixa iimodeli ezine-shaft zifikelela kwi-$ 500,000. Iindleko eziqhubekayo zokulondoloza nokusebenza zongeza ucelomngeni. Amanye amashishini akhetha ezinye iindlela ezingabizi kakhulu, nto leyo enciphisa ukukhula kobuchwepheshe obutsha.

Eminye imiqobo ibandakanya ubunzima bobugcisa kunye nesidingo sabasebenzi abanezakhono. Iigranulator ezihlakaniphile zisebenzisa i-IoT kunye ne-AI, kodwa abaqhubi kufuneka bafunde izakhono ezitsha ukuze baziqhube kakuhle. Iingxaki zekhonkco lonikezelo kunye nokunyuka kwamaxabiso ezinto ezikrwada kunye namandla nako konyusa iindleko. Iinkampani zijongana nokungaqiniseki kuba imithetho iyahluka ngokweendawo. Abavelisi bazama ukunceda ngokuyila oomatshini abangabizi mali ininzi, bakhangele iindawo ezithile ekuhlaleni, nokusebenza nabalawuli.

Qaphela: Uqeqesho lwabasebenzi kunye nokwehliswa kweendleko kunokunceda iinkampani ezininzi zithathele ingqaleloizixhobo zokurisayikilisha eziphambili.

| Umqobo | Impembelelo kuMbatho Womntwana |

|---|---|

| Iindleko zokuqala eziphezulu | Imida yokufikelela kumashishini amancinci |

| Ukuntsokotha kobugcisa | Ifuna abasebenzi abanezakhono |

| Ukungaqiniseki ngolawulo | Icothisa ukwenza izigqibo |

| Imiba yekhonkco lonikezelo | Inyusa iindleko zokusebenza |

Uphuhliso olulindelekileyo luka-2025 nokuNgaphaya

Iingcali zoshishino zilindele utshintsho olukhulu kwiminyaka embalwa ezayo. I-automation kunye neempawu ezihlakaniphile ziya kwenza ukuba oomatshini bakhawuleze kwaye kube lula ukuyisebenzisa. I-AI kunye ne-IoT iya kunceda abaqhubi babeke iliso kwiinkqubo, baqikelele iingxaki, kwaye bagcine amandla. Iigranulator zohlobo lwe-Rotor ziya kuphucula ukusika kunye nokusingatha iintlobo ezininzi zeeplastiki. Iinkampani ziya kuyila oomatshini bemijelo ethile yenkunkuma, yenze ukuba ukurisayikilisha kusebenze ngakumbi.

Ukuzinza kuya kuhlala kuyinjongo ephezulu. Abavelisi baya kusebenzisa izinto ezinokuphinda zisetyenziswe kunye noyilo lweemodyuli ukuxhasa uqoqosho lwesetyhula. Imithetho engqongqo yokukhutshwa kunye nengxolo iya kubumba iimveliso ezintsha. Inkxaso-mali evela koorhulumente kunye nabatyali-mali iya kukhawulezisa ukuveliswa kweteknoloji eluhlaza. Ukukhula kuya komelela e-Asia Pacific, kuMntla Melika, naseYurophu njengoko amashishini amaninzi efuna izisombululo ezingcono zokurisayikilisha.

- I-Automation kunye ne-AI iya kukhulisa ukusebenza kakuhle.

- Ukuphuculwa kweemodyuli kuya kwenza ukuba oomatshini bahlale ixesha elide.

- Izisombululo zesiko ziya kufanela amashishini ahlukeneyo.

- Imigaqo iya kutyhala izixhobo ezicocekileyo nezithuleyo.

Icebiso: Iinkampani ezityala imali koomatshini abakrelekrele, abagcina amandla baya kuhlala bephambili njengoko imarike ikhula kwaye imithetho iyatshintsha.

Ukuzenzekela, ukusebenza kakuhle kwamandla, kunye nokuphatha izixhobo eziphambili kubumba ikamva layo yonke igranulator yeplastiki. Iinkampani zibona izibonelelo ezifana neendleko eziphantsi, umgangatho wemveliso ongcono, kunye nokuthobela lula.

- Izinzwa ze-Smart kunye ne-automation yonyusa imveliso.

- Uyilo olugcina amandla lunciphisa inkcitho kunye nokuxhasa uzinzo.

- Ukubeka esweni iindlela ezintsha kunceda amashishini ahlale phambili.

FAQ

Yintoni eyenza igranulator yeplastiki "inzima-umsebenzi"?

Umsebenzi onzimaigranulator yeplastikiisebenzisa iindawo ezomeleleyo kunye neenjini ezinamandla. Iyakwazi ukuphatha iiplastiki ezinzima okanye ezinkulu ngaphandle kokuphuka.

Ngaba izinzwa ezikrelekrele zinceda njani kwiigranulator zeplastiki?

Izinzwa ze-Smart watch umatshini wokujonga impilo kunye nokusebenza. Bazisa abaqhubi kwiingxaki kwangethuba. Oku kugcina igranulator isebenza ixesha elide kwaye inciphisa ixesha lokuphumla.

Ngaba ezi granulator zitsha zingawonga amandla?

Ewe! Uyilo olutsha lusebenzisa iinjini eziphezulu kunye nolawulo oluhlakaniphile. Ezi mpawu zinceda iinkampani ukuba zinciphise iindleko zamandla kunye nokuxhasa iinjongo eziluhlaza.

Ixesha lokuposa: Aug-13-2025