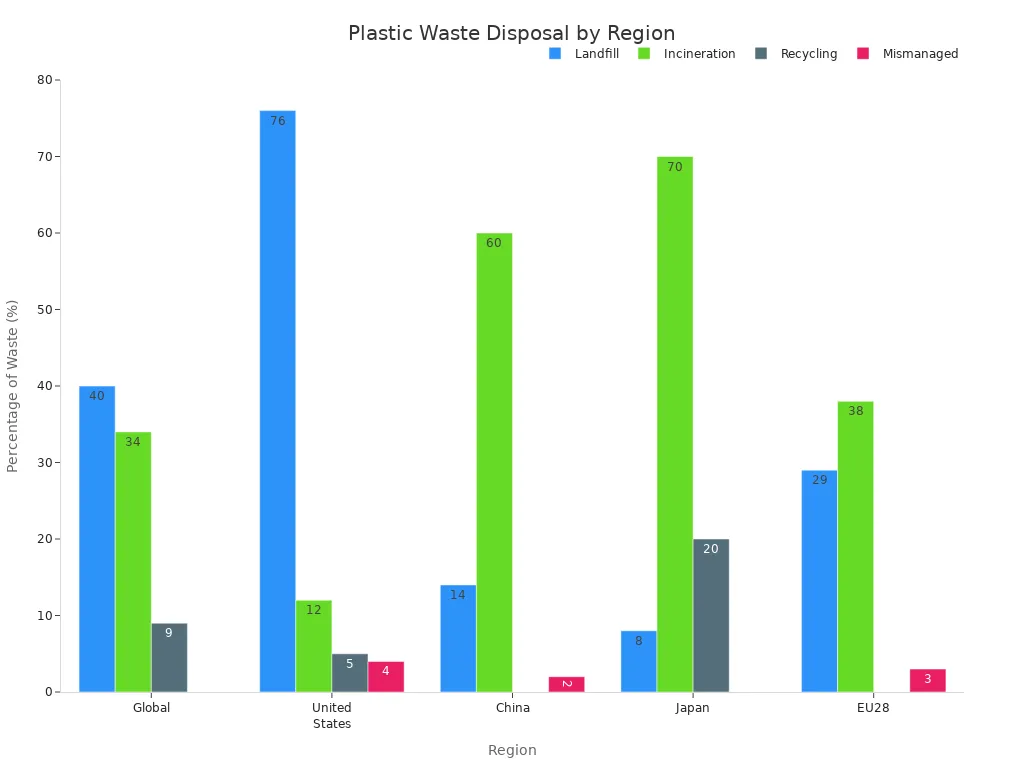

Inkunkuma yeplastiki iyakhula, malunga neetoni ezizigidi ezingama-400 eziveliswe kwihlabathi liphela ngo-2022. Yi-9% kuphela ehlaziywayo, njengoko kubonisiwe ngezantsi.

Ukukhetha phakathi kwe-aUmatshini wePlastiki weGranulatorkunye aIPlastiki Shredderiyatshintsha njaniOomatshini bokurisayikilisha bePlastikiumsebenzi.

- Igranulatoryenza amaqhekeza amancinci, afanayo ukuze kube lula ukurisayikilishwa.

- I-Plastiki Shredder iphatha i-scrap eninzi kunye nezixhobo ezinzima.

Ukukhetha umatshini ochanekileyo kukhuthaza ukusebenza kakuhle.

| Iinkcukacha-manani / iNgingqi | Ixabiso / Inkcazo |

|---|---|

| Ukuveliswa kwenkunkuma yeplastiki yehlabathi jikelele | ~ I-400 yezigidi zeetoni ngo-2022 |

| Izinga lokurisayikilishwa kwehlabathi | Malunga ne-9% (imile) |

| Umlinganiselo wokurisayikilisha eMelika | I-5% ihlaziywe, i-76% ifakwe inkunkuma, i-12% itshisiwe, i-4% ilawulwa gwenxa |

| Izinga lokutshiswa kweJapan | 70%, itiphu 8%, ukurisayikilisha ~20% |

Izinto eziphambili zokuThatha

- Izitshizi zeplastikiqhekeza inkunkuma yeplastiki enkulu, eyomeleleyo ibe ziziqwenga ezinkulu, izenze zilungele ukuphatha izinto ezinkulu okanye ezixubeneyo ekuqaleni kokurisayikilishwa.

- Igranulator yeplastikioomatshini basika iplastiki ibe yigranule encinci, iyunifomu, ilungele ukucoceka, izilahlwa ezicwangcisiweyo kwaye zilungele ukuphinda zisetyenziswe ekubumbeni okanye kwi-extrusion.

- Ukukhetha umatshini ochanekileyo kuxhomekeke kuhlobo lwakho lweplastiki kunye nobukhulu: sebenzisa i-shredders kwizinto ezinkulu, ezinzima kunye neegranulator zokusulungekisa amaqhekeza amancinci kwiigranules ezifanayo.

Umatshini weGranulator yePlastiki vs. I-Plastiki Shredder: Iinkcazo kunye neMigaqo yokuSebenza

Yintoni umatshini wePlastiki weGranulator?

A Umatshini wePlastiki weGranulatorsisixhobo esisika inkunkuma yeplastiki ibe ngamaqhekezana amancinci afanayo. Aba matshini banceda amaziko okurisayikilisha kunye neefektri zijika iiplastiki ezilahliweyo zibe ngamaqhekeza alungele ukusetyenziswa kwakhona. Basebenza kakuhle ngezinto ezifana ne-sprues, iimbaleki, i-movie edges, kunye ne-start-up scrap. Uninzi lweegranulator zisebenzisa i-rotor enye eneemela ezibukhali ukusika iplastiki.

Iigranulator zidume ngokusetyenzwa kweeplastiki eziqhelekileyo ezifana ne-polyethylene, i-polypropylene, kunye ne-polystyrene.

Usebenza njani umatshini wePlastiki weGranulator?

Inkqubo iqala xa abasebenzi befaka iplastiki kwi hopper. Ngaphakathi kwegumbi lokusika, ii-blades ezijikelezayo zisika izinto ngokubhekiselele kwi-fixed blades. Isikrini okanye i-mesh ihluza iigranules, ivumela kuphela ubungakanani obufanelekileyo ukuba budlule. Iziqwenga ezinkulu zibuyela umva ukusika ngaphezulu. Injini inika amandla iincakuba kwaye ilawula isantya. Iigranule ezigqityiweyo ziqokelela kwi-bin, zilungele ukubunjwa okanye ukukhupha.

- Amalungu aphambili:

- Hopper

- Igumbi lokusika

- Iincakuba ezijikelezayo kunye nezilungisiweyo

- Isikrini okanye umnatha

- Iimoto kunye nenkqubo yokuqhuba

- Umgqomo wokuqokelela

Yintoni iPlastiki Shredder?

A iplastiki shredderngumatshini owenzelwe ukophula inkunkuma eninzi, eyomeleleyo yeplastiki. I-Shredders iphatha izinto ezifana ne-bumpers yemoto, amagubu kunye nemibhobho. Basebenzisa isantya esicothayo kunye netorque ephezulu ukukrazula iiplastiki zibe ziziqwenga ezinkulu, ezingalinganiyo. I-shredders iza kwiindidi ezahlukeneyo, ezifana ne-shaft enye, i-double-shaft, kunye neemodeli ezine-shaft.

| Uhlobo lweShredder | Iindidi zeNkunkuma yePlastiki ezifanelekileyo |

|---|---|

| Isigrisi | Iiplastiki ezinzima kunye nezinkulu |

| IiChippers | Iiplastiki eziqinileyo; izinto ezinkulu ezifana neekhreyithi, iipalethi |

| Shear Shredders | Iiplastiki ezinkulu, ezityebileyo; amagubu, imibhobho |

| IiShredders zeNjongo zonke | Inkunkuma yeplastiki edibeneyo |

Isebenza njani iPlastiki Shredder?

Iiplasitiki shredders zisebenzisa iiblade ezinamandla ezifakwe kwishafts. Lo matshini ubamba kwaye utsale iplastiki, emva koko uyikrazule. Imveliso inkulu kwaye ingaphantsi ngokufanayo kuneegranule zegranulator. Iishredders zihlala zisebenza njengenyathelo lokuqala lokuphinda zisetyenziswe, zisenza amaqhekeza amakhulu abe mancinci ngokwaneleyo ukuba aqhubeke nokuqhubekeka.

I-Shredders isebenza ngokuzolileyo kwaye ibandakanya iimpawu zokhuseleko ezifana nokubuyisela umva kunye nezithinteli zetorque.

Ukuthelekisa iPlastiki yeGranulator Machine kunye nePlastiki Shredder: Umahluko oPhambili

INkqubo yokuSebenza kunye nokuSika

Indlela aba matshini babini basika ngayo iplastiki yahluke kakhulu. Iigranulator zisebenzisa iincakuba ezibukhali, ezihamba ngokukhawuleza ezisika iplastiki ibe ngamaqhekeza amancinci. Basebenza ngesantya esiphezulu, ngokuqhelekileyo phakathi kwe-400 kunye ne-800 rpm, kwaye basebenzisa i-torque ephantsi. Iincakuba zazo zincinci kwaye zenzelwe ukuchaneka. Olu luyilo lubanceda ukuba basike izilaphu zeplastiki ezicocekileyo, ezihleliweyo zibe ziigranuli ezifanayo.

Ii-shredders zona zisebenzisa iincakuba ezingqindilili, ezomeleleyo ezihamba kancinane kodwa ngamandla amaninzi. Ngokuqhelekileyo zibaleka kwi-10 ukuya kwi-130 rpm. Iincakuba zazo zinamagwegwe okanye amazinyo kwaye ziyakwazi ukuphatha inkunkuma enkulu okanye exutyiweyo yeplastiki. Iishredders zikrazula kwaye zophula izixhobo ezomeleleyo, zizenza zibe ntle kwinyathelo lokuqala lokurisayikilisha.

Nantsi ukujonga okukhawulezayo kwindlela iiblade zabo zithelekisa ngayo:

| Uphawu | IiBlayisi zePlastiki zeGranulator | IiBlayisi zePlastiki zeShredder |

|---|---|---|

| Isantya sokuSebenza | Isantya esiphezulu (400–800 rpm) | Isantya esisezantsi (10–130 rpm) |

| Ukusika Mechanism | Ukucheba kwimela yebhedi emileyo | Ukukrazula ngamacangca okanye amazinyo kwiishafu ezininzi |

| Imilo yeBlade | Iimela ezibukhali, ezenziwe ngobunjineli obuchanekileyo | Abaqingqisi, abasiki bomelele ngakumbi |

| Ukuqina kwezinto | Iintsimbi ezinobunzima obuphezulu njenge-D2 okanye i-SKD11 | Ukumelana nempembelelo, yenzelwe ukuqina |

| Isicelo | Iiplastiki ezicocekileyo, ezilungiswe kwangaphambili (umzekelo, iinxalenye ezibunjiweyo) | Inkunkuma eninzi, engcolisekileyo, okanye eqinileyo yeplastiki |

| Injongo | Ivelisa iigranuli ezincinci, ezifanayo ukuze ziphinde zisetyenziswe | Uqhekeza izinto ezinkulu okanye ezinzima zibe ziziqwenga |

Ingcebiso: Iigranulator zezona zingcono kwiplastiki ecocekileyo, ehleliweyo. I-Shredders ingcono kwi-bulky, ixutywe, okanye iplastiki engcolileyo.

Ubungakanani besiphumo kunye nokuhambelana

Iigranulator kunye neeshredders zivelisa iziphumo ezahlukeneyo kakhulu. Iigranulators zenza amancinci, kunye namaqhekeza. Iigranule ezininzi zimalunga ne-10mm nge-10mm, kwaye ubungakanani bunokulungiswa ngokutshintsha isikrini. Ubungakanani obuqhelekileyo bujikeleze i-12mm, kodwa bunokusuka kwi-8mm ukuya kwi-20mm. Lo bungakanani obufanayo benza ukuba iigranuli zisetyenziswe ngokulula kwiimveliso ezintsha.

Iishredders zenza amaqhekeza amakhulu, arhabaxa. Amaqhekeza ahlala ajikeleze i-40mm kwaye anokwahluka kakhulu ngobukhulu kunye nokumila. Ezi ziqwenga zihlala zifuna ukuqwalaselwa ngakumbi ngaphambi kokuba zisetyenziswe kwakhona. Iigranulator zinika imveliso engaguqukiyo, ngelixa i-shredders igxile ekwaphuleni izinto ezinkulu ngokukhawuleza.

- Iigranulator: Ezincinci, iigranuli ezifanayo (malunga ne-10mm x 10mm)

- I-Shredders: Iziqwenga ezinkulu, ezingalinganiyo (malunga ne-40mm), azihambelani kakhulu

Izinto Zokubamba Izinto

I-Shredders inokuphatha phantse nantoni nauyabagibisela. Zisebenza ngeplastiki engqingqwa, enkulu, okanye emile ngendlela engaqhelekanga. Ubungakanani obukhulu begalelo buxhomekeke kwizibuko lokutya kunye namandla emoto. Ezinye iishredders zinokuthatha iziqwenga ezinkulu njenge-1000 × 500 mm. Bangakwazi ukucubungula iiplastiki ezinobunzima ukusuka kwi-0.7 mm ukuya kwi-12 mm okanye ngaphezulu, kuxhomekeke kumatshini.

Iigranulator zifuna amaqhekeza amancinci, acocekileyo. Basebenza kakuhle ngezinto ezifana ne-sprues, iimbaleki, iibhotile, kunye nemiphetho yefilimu. Izinto ezinkulu okanye ezityebileyo kufuneka zophulwe phambi kokuba zingene kwigranulator. Ukuba iplastiki ibhityile kakhulu, njengefilimu, inokutyibilika kwiincakuba ze-shredder endaweni yokunqunyulwa.

Qaphela: Iishredders zezona ndlela zokuya kwimisebenzi emikhulu, enzima. Iigranulators zigqibelele ukucokisa ama-scraps amancinci, acocekileyo.

Izicelo eziqhelekileyo kunye neemeko zokuSebenzisa

Iigranulator kunye neeshredders zombini zidlala indima ebalulekileyo ekusetyenzisweni kwakhona, kodwa zingena kwiindawo ezahlukeneyo zenkqubo.

Umatshini wePlastiki weGranulatorixhaphakile kwi:

- Izitofu zokubumba izityalo (ukusebenzisa kwakhona izihluzi, iimbaleki, kunye namalungu anesiphene)

- Iiyunithi zokubumba ezivuthelayo (iibhotile zokuphinda zisetyenziswe kunye nezikhongozeli)

- Iiyunithi ze-Extrusion (ukubuyisela ukucutha kunye neeprofayili ezingaphandle kwe-spec)

- Iiyunithi zokwenza iidana zeplastiki (ukwenza iigranule zepelletizing)

- Izityalo zeplastiki zokurisayikilisha (ukuguqula iplastiki yasemva komthengi ibe yimathiriyeli ekrwada)

- Umzi-mveliso wokupakisha (ukulungisa kwakhona amalaphu efilim kunye nenkunkuma yamaphepha)

| Icandelo lezoShishino | Ukusetyenziswa okuqhelekileyo koomatshini bePlastiki beGranulator |

|---|---|

| Isitofu sokubumba izityalo | Ukusetyenziswa kwakhona kwesprues, iimbaleki, kunye neendawo ezibunjiweyo ezineziphene |

| Vuthela iiYunithi zokuBumba | Ukurisayikilisha iibhotile, amagubu, kunye nezikhongozeli ezingenanto |

| Extrusion Units | Ukubuyiswa kwee-trimmings kunye neeprofayili ezingaphandle kwe-spec okanye amaphepha |

| IiYunithi zokwenziwa kweDana zePlastiki | Inkqubo yokutya ukuvelisa iigranules ze-pelletizing |

| Izixhobo zePlastiki zokuRecycling | Ukuguqulwa kweplastiki yasemva komthengi ibe yimathiriyeli ekrwada yesibini |

| Ishishini lokuPakisha | Ukuphinda kucutshungulwe iimvuthuluka zefilimu, ukusonga amaqamza, kunye nenkunkuma yamaphepha |

Iishredders zisetyenziswa kwi:

- Amaziko okurisayikilisha (ukuqala ukucoca, iikhreyiti, iipalethi, imibhobho, izikhongozeli)

- Izixhobo zokuvelisa (ukuphatha iindawo ezibunjiweyo kunye nenkunkuma yasemva kwabathengi)

- Ulawulo lwenkunkuma yabathengi (iibhotile zePET, ukupakishwa)

- Imizi-mveliso yeemoto kunye neyombane (ukulungisa iiplastiki ezomeleleyo kunye nenkunkuma exutyiweyo)

- Ukulungiswa kwezonyango kunye nokutya (ukulahlwa ngokukhuselekileyo kwenkunkuma yeplastiki)

- Ukurisayikilishwa kwefilimu yezolimo

- I-Shredders iphatha uluhlu olubanzi lweeplastiki, irabha, iifayibha, kunye nezinto ezinzima ezifana neKevlar kunye nekhabhoni.

- Zikwasetyenziselwa ukurisayikilisha kwamatayara, inkunkuma eyingozi, kunye nokulungiswa kweentsimbi ezilahliweyo.

AbakwaShredders baqala inkqubo yokurisayikilisha ngokophula izinto ezinkulu. Iigranulators zigqiba umsebenzi ngokwenza iigranuli ezincinci, ezinokuphinda zisebenziseke.

Itheyibhile yokuthelekisa ecaleni-ngecala

Nantsi itheyibhile ukukunceda ubone umahluko ongundoqo ngokukrwaqula nje:

| Umgangatho wokuSebenza | Umatshini wePlastiki weGranulator | IPlastiki Shredder |

|---|---|---|

| Ukusika Mechanism | Isantya esiphezulu, ukusika ngokuchanekileyo | Isantya esisezantsi, ukukrazuka kwetorque ephezulu |

| Ubungakanani bemveliso | Iigranule ezincinci, ezifanayo (8–20mm) | Iziqwenga ezinkulu, ezingaqhelekanga (ukuya kuma-40mm+) |

| Ukuphatha Izinto | Coca, ihlelwe kwangaphambili, iziqwenga ezincinci | Iiplastiki ezinkulu, ezixubileyo, okanye ezingcolisekileyo |

| Usetyenziso oluqhelekileyo | Isitofu ukubumba, extrusion, ukupakisha | Amaziko okurisayikilisha, ulawulo lwenkunkuma, auto |

| Iimfuno Zokulondolozwa | Iindawo ezisezantsi, ukufikelela lula | Ephakamileyo, ukutshintshwa kwe-blade rhoqo |

| Umthamo wokuPhumeza | Phakathi (200–300 kg/yure) | Phezulu (ukuya kwiitoni ezi-2 ngeyure) |

| Iindleko zokuSebenza | Amandla aphantsi kunye nokugcinwa | Abasebenzi abaphezulu kunye nenxalenye yeendleko |

| Ukudityaniswa | I-Standalone okanye i-granulators ephakathi | I-Standalone okanye idibaniswe ne-granulators |

Ukukhetha umatshini ochanekileyo kuxhomekeke kuhlobo lwakho lwemathiriyeli, isiphumo esifunekayo, kunye nalapho ungena khona kwinkqubo yokurisayikilisha.

Ukukhetha phakathi kwePlastiki yeGranulator Machine kunye nePlastiki Shredder

Uhlobo lweMathiriyeli kunye nokuqwalaselwa kobungakanani

Ukukhetha umatshini ochanekileyo kuqala ngokujonga uhlobo kunye nobukhulu benkunkuma yeplastiki. Iishredders zisebenza kakuhle kwizinto ezinkulu, ezinkulu ezifana namagubu, imibhobho, okanye iibhampa zemoto. Ziziqhekeza zibe ziingceba ezincinci, zenze kube lula ukuphatha. I-Granulators ithatha indawo xa iplastiki sele isele incinci okanye emva kokuqhawula. Bacokisa izinto eziphathekayo kwiigranule ezifanayo. Itheyibhile engezantsi ibonisa ukuba umatshini ngamnye uhambelana njani neemfuno ezahlukeneyo:

| Umba | Umatshini wePlastiki weGranulator | IPlastiki Shredder |

|---|---|---|

| Ubungakanani beSilaphu kunye nesantya sokutya | Ukukhanya ukuya kwinkunkuma ephakathi | Enkulu, inkunkuma eninzi |

| Ubungakanani besiphumo kunye neNjongo | Iigranule ezifanayo | Iingceba ezirhabaxa |

| Iimpawu zoMsebenzi | I-RPM ephezulu, i-torque ephantsi | I-torque ephezulu, ephantsi-RPM |

| Ukulinganiselwa | Ukulwa ngamalungu anzima | Ayilunganga kwizilaphu ezikhanyayo |

Icebiso: Kwiiplastiki zobunjineli kwifom yentonga okanye kwiplate, i-shredder kufuneka ihambe kuqala, ilandelwa yigranulator ngeziphumo ezilungileyo.

Isiphumo esinqwenelekayo kunye nokuphelisa ukusetyenziswa

Ukusetyenziswa kokugqibela kweplastiki esetyenzisiweyo ikhokela ukhetho phakathi koomatshini. Iigranulators zivelisa amancinci, nkqu iigranules, ezilungele ukubumba inaliti, i-extrusion, okanye ukubumba ukuvuthela. Iishredders zenza amaqhekeza amakhulu, arhabaxa ahlala efuna ukusetyenzwa ngakumbi. Itheyibhile engezantsi ibalaselisa ubungakanani obucetyiswayo bemveliso kusetyenziso olwahlukileyo:

| Ukuphelisa ukusetyenziswa / Inkqubo | Ubungakanani bemveliso ecetyiswayo (mm) | Injongo / Inzuzo |

|---|---|---|

| Isitofu ukubumba, extrusion | 6.35 - 9.5 | Ukusetyenziswa ngokuthe ngqo kwimveliso |

| WEEE iiflake zeplastiki zokuhlela | 10 – 20 | Ukuphucula ukuhlenga-hlengisa kunye nokusebenziseka kwakhona |

Indlela yenyathelo ngenyathelo inceda ukuthelekisa umatshini nomsebenzi:

- Khangela ukuba iplastiki iyaguquguquka okanye iqinile.

- Jonga ubungakanani kunye nokumila.

- Cinga ngosulelo.

- Tshatisa umatshini kwizinto eziphathekayo kunye neemfuno zemveliso.

- Qwalasela iindleko kunye nendawo.

Imiba yokuSebenza: Isantya, uLondolozo, kunye neendleko

Isantya, ukugcina, kunye neendleko xa ukhetha umatshini. Iigranulator zibaleka ngesantya esiphezulu kwaye zenze amasuntswana acolekileyo. Bafuna ukulola incakuba rhoqo kodwa basebenzise amandla amancinci. AbakwaShredders basebenza kancinci, basebenzise itorque eninzi, kwaye baphathe imisebenzi enzima. Babiza ngaphezulu ukuqhuba nokugcina, ngakumbi kwiimodeli ezinobunzima. Le theyibhile ingezantsi ithelekisa ezi meko:

| Uphawu | Umatshini wePlastiki weGranulator | IPlastiki Shredder |

|---|---|---|

| Isantya sokuSebenza | Phezulu | Phantsi |

| Ubungakanani bemveliso | Incinci, iyunifomu | Enkulu, ezahlukeneyo |

| Isondlo | Ukhathalelo lwe-blade rhoqo | Ukutshintshwa kweblade rhoqo |

| Iindleko | Ngasezantsi | Phezulu |

Qaphela: Amaziko anenkunkuma eninzi kakhulu anokukhetha ii-shredders, ngelixa ezo zifuna iigranuli ezilungileyo nezisebenzisekayo zihlala zikhetha iigranulator.

Ukukhetha umatshini ofanelekileyo kubalulekile. Iishredders ziqhekeza iiplastiki ezinkulu kuqala, ngelixa iigranulator zenza amaqhekeza amancinci, afanayo ukuze aphinde asetyenziswe. Zombini zidlala indima ephambili ekusetyenzisweni ngokutsha. Ukufumana ireferensi ekhawulezayo, jonga le theyibhile ngeengcebiso zeengcali ekukhetheni eyona nto ifanelekileyo kwi-scrap yakho kunye nenkqubo:

| Umba | Igranulator | Shredder |

|---|---|---|

| Isantya | Phezulu | Phantsi |

| I-Scrap Volume | Nawuphi na ubungakanani | Eyona nto ingcono kwiimali ezinkulu |

| Ubungakanani bemveliso | Incinci, iyunifomu | Enkulu, rhabaxa |

FAQ

Zeziphi iiplastiki ezinokuthi inkqubo yomatshini wegranulator?

Igranulator iphatha iiplastiki ezicocekileyo, ezicwangcisiweyo njengeebhotile, i-sprues, kunye nemiphetho yefilimu. Isebenza kakuhle ngezinto ezifana ne-polyethylene, i-polypropylene, kunye ne-polystyrene.

Ngaba i-shredder kunye ne-granulator zingasebenza kunye?

Ewe! Uninzi lwezityalo eziphinda zisetyenziswe zisebenzisa ishredder kuqala kwizinto ezinkulu. Emva koko, basebenzisa igranulator ukwenza iigranule ezincinci, ezifanayo.

Kufuneka abasebenzi babagcine kangaphi aba matshini?

Abanini-zithuthi kufuneka bajonge iiblade ngeveki. Kufuneka zilole okanye zitshintshe njengoko zifuneka. Ukucoca rhoqo kugcina bobabini oomatshini besebenza kakuhle kwaye bekhuselekile.

Ixesha lokuposa: Aug-14-2025